3D Digital Prototyping: How It Revolutionized The Process of Product Design

Some technologies have a reputation for changing the way we see the world. Take, for instance, the typewriter, which introduced standardized documentation. Or fax machines, which helped transfer documents faster through telephone systems. And more recently, personal computers, which have brought in an age of new products and services we now cannot imagine our lives without. Now, in the context of product design, 3D digital prototyping has a similar position.

The 3D modeling technology, which allows designers to virtually explore the product before it ever becomes real, offers unparalleled benefits. Overall, manufacturers using virtual prototyping build a lesser number of physical prototypes, launch their products earlier, and incur much lower costs. In a world where the pressure on business performance is always increasing, digital prototyping is a heaven-sent solution.

But how did this technology bring about such a radical change? Read on and learn about the 7 key ways in which digital 3D prototyping revolutionized the process of product design!

#1. Digital 3D Prototyping Improved The Conceptual Design Phase

The conceptual design phase is the earliest stage of any prototyping process. It involves the designers researching market conditions and manufacturers’ needs in order to create a product design concept. In conventional prototyping workflows, this is a long-drawn process where every one of these actions is performed separately.

In a 3D digital prototyping workflow, however, designers can work digitally right from the first sketch till the end of the conceptual design phase. Designs are both captured and reviewed as high-quality digital 3-dimensional images. The designs are also shared in a common file format. Data and feedback obtained from this process are then directly used to make informed product decisions in real time.

#2. It Simplified The Product Development Cycle

In traditional prototyping, identifying and applying changes is laborious. Designers first have to build a physical prototype, test it, then make changes according to their observations — all to create a single working prototype. Errors can only be identified once the physical prototype has been built, and the only way to make changes is to build a fresh one. While effective in the long run, this uses up a lot of time, money, and materials. 3D digital prototyping essentially disrupted this process.

As designers can now analyze concepts in real-life environments within the software, it eliminates the need to build physical prototypes first. Rather, the cycle now starts with the digital analysis and testing of a virtual model. Only when the model is found to be perfect is the physical prototype made.

#3. 3D Digital Prototyping Allowed for Creating Stunning Promo Visuals

Under conventional prototyping, creating visuals for marketing products is largely done through physical photography. This can only be done once the product was completely ready to market — which is naturally very time-consuming. 3D digital prototyping has turned this process on its head by allowing manufacturers to obtain gorgeous photorealistic images long before the product actually gets ready for the market. These images are as accurate as physical photographs. Moreover, it’s possible to create interactive digital visuals, such as 360-degree-views.

Having 3D rendered visuals at hand makes it easier to create marketing materials and helps product marketers launch their campaigns on time. This offers multiple benefits to marketers as they can easily build up the hype around their products through their social media pages, as well as digital and printed catalogs. Furthermore, companies can use 3D renders to take pre-orders from interested B2B customers.

#4. It Helped Companies Reduce Their Carbon Footprint

Physical prototyping-based workflows are characterized by the constant cycle of “build-test-build.” Time and cost factor aside, this leads to a lot of material wastage. In the age where there are statutory laws and regulations around being sustainable, and the need to maintain corporate social responsibility is the norm, this is a major disadvantage.

Now, 3D digital prototyping helps companies up their sustainability quotient in many ways. Firstly, virtual testing reduces the number of required physical prototypes, which reduces the bulk of material waste. Secondly, the ability to assess various options within the product design 3D modelling software gives the exact description of the type and quantity of material necessary to build a singular physical prototype. This takes any guesswork out of the equation. Last but not the least, the data obtained by running various digital simulations gives companies the idea of how various materials compare with the existing environmental regulations and sustainability standards.

#5. Virtual Prototyping Improved Communication With Manufacturers

Communication between designers and manufacturers in the age of conventional prototyping is known to be tedious and time-consuming. With the entire process dependent on building prototype after prototype, keeping manufacturers in the loop is difficult, and their opinions are factored in only during the later stages of prototype development.

The use of 3D digital prototyping has greatly improved the development workflow by bridging the gap between designers and manufacturers. Thanks to convenient digital formats, prototypes can now be shared anytime and anywhere. This helps bring manufacturers on board right from the early stages of product development. Manufacturers can now see their product being developed in real time, and offer instant feedback and input on the manufacturability.

#6. It Contributed to Improvement of the Rapid Prototyping Process

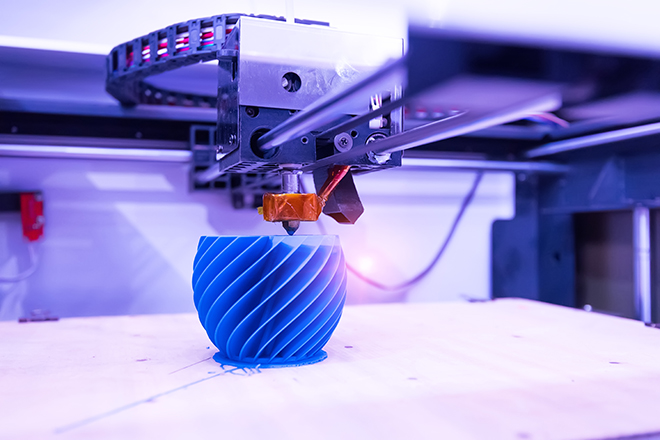

It is a known fact that companies are increasingly resorting to smarter ways of production to cope with the pressures of business performance. Rapid prototyping happens to be one of these methods. As the name suggests, this is the system of swiftly fabricating parts, models, and assemblies using Computer-Aided Design (CAD) and 3D printing. This helps in creating prototypes faster without compromising on their quality. And up until the recent past, this has helped designers create their multiple physical prototypes faster.

3D digital prototyping, however, puts an even faster spin on the already rapid process. By allowing designers to fully test, edit, and run digital simulations on their prototypes for functionality, accuracy, and finish, the need for multiple 3D printed prototypes to test is removed. This allows for testing very realistic prototypes with lesser effort, much earlier in the design process. And when the digital prototype is finally ready, it is fully optimized for physical prototyping.

#7. Virtual Prototyping Allowed Companies to Save Time And Money

As mentioned earlier, multiple edits and changes are a norm with physical prototyping. Among other things, this ends up consuming a huge amount of time and money just to create a single working prototype. With 3D digital prototyping, however, both these factors get cut down to the minimum.

Creating a prototype in digital format has a two-fold benefit. Firstly, since designers no longer have to make multiple physical prototypes, the total time spent on the average is much lesser. Secondly, 3D modeling can easily be outsourced. This is simple and affordable since it saves companies from going through the hassles of hiring in-house specialists and buying expensive hardware and software. Both these factors together help bring about a more positive Return-on-Investment (ROI).

So, these were the 7 ways in which 3D digital prototyping has changed the way products are now designed. This method helps designers test the form, fit, and function of the prototype in a real-world context — while staying within the digital framework. This has multiple benefits — a more compact conceptual design phase, a more competitive and sustainable prototype, fewer errors, better collaboration with manufacturers, more seamless rapid prototyping, and of course, less overall time and money spent. All of these together have led to designers choosing digital prototyping over other methods, which, in turn, has changed the process of product design entirely.

Looking for 3D modeling and rendering services to rocket launch your products? Contact us at UFO3D today - our professional team is always ready to create extremely photorealistic 3D models of even the most complex designs!

Let us know if you’ve got an interesting project and want to work together!