History of 3D Printing in a Nutshell

3D printing has become a media star recently, revolutionizing many industries and becoming more advanced every year. Now, 3D-printed materials are being used to construct buildings in record times. Complex electronics can be manufactured at home in hours with a bit of know-how. Functional 3D-printed prosthetics have made body part replacement much more accessible for disabled people. There are even currently ongoing experiments aimed at using additive manufacturing to create organic body parts and organs for transplantation! This technology is truly fascinating and has lots of untapped potential, which we are bound to experience in years to come.

3D printing is so awesome that it’s hard to browse the Internet without stumbling on articles exploring its greatness. But how did 3D prototypes and models come to be? Join us as we delve into the history of 3D printing!

#1. First 3D-printed objects

The history of additive manufacturing begins, as with any groundbreaking invention, with a desire to make something complex easier. And, of course, with fierce competition. Technically, the history of 3D printing started when a Japanese inventor Hideo Kodama patented a system for curing resin with a laser in 1981. Sadly, the project was dropped due to the lack of funding. In 1984, a group of talented French researchers, lead by Alain le Méhauté, has independently come up with their version of the 3D printing process. It failed, again, due to the lack of money.

Despite initial setbacks, the idea of additive manufacturing persisted. Just three weeks after Méhautés patent fell through, Charles Hull, a brilliant American manufacturer with a knack for inventions, has come up with a way to cure resin with UV lamps. He patented this technology under the name of “stereolithography”. In 1986, Hull founded 3D Systems, the first 3D printer manufacturing company, which is a market leader to this day.

#2. The innovations of the late 1980s

The end of the 1980s is the age of innovation in the history of 3D printing. As the first commercial 3D printers have entered the market, two new major technologies were invented to enhance the process. They have changed largely experimental stereolithography into what we know as 3D printing today.

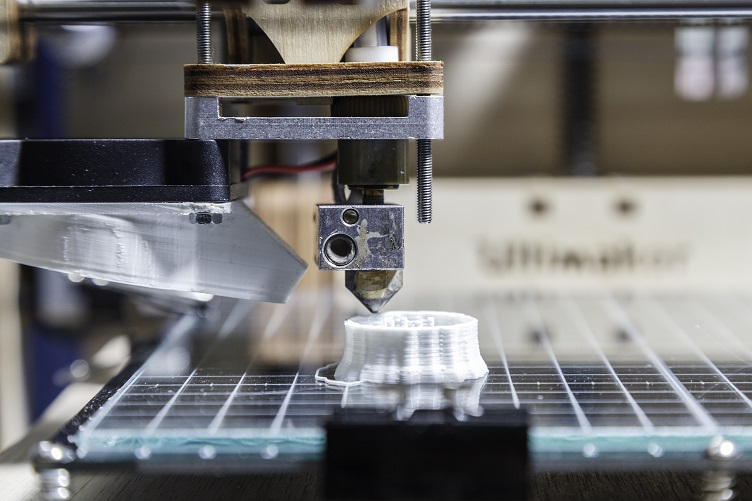

The first one was selective laser sintering, or SLS, patented by Carl Deckard in 1988. In layman’s terms, it allowed 3D printing machines to replicate fine details on plastic objects. Before SLS, resin curing was only capable of producing relatively basic three-dimensional shapes.

The second technology was fused deposition modeling, or FDM, created in 1989. Its inventor was Scott Crump, co-founder of Stratasys, another 3D printing giant that exists today. FDM essentially defined how modern 3D printers work: filament melted by a heating element is pushed out of a small tube, the resin quickly solidifies, shaping objects layer by layer. This method not only made the process cheaper but also much faster and efficient material-wise.

#3. The 1990s: the rise of metal printing

The 1990s are a crucial period in the history of 3D printing. Before that, printing metal objects was incredibly difficult or outright impossible due to hardware limitations and low power of lasers. Even though it was technically possible to print small metal objects like screws, manufacturers still relied on machining small parts. But with the influx of more powerful equipment, printing small and medium-sized metal details became not only possible but financially viable. The 3D printing machines themselves became capable of recreating fragile support structures for complex 3D models with precise droplet application of resin. On top of that, powerful compact lasers allowed carving extremely fine details with ease. This period of history provided a solid base for innovative technologies to come.

#4. The early 2000s: popularization of 3D printing

The 2000s were an important period in the history of 3D printing. It happened for several reasons. First of all, 3D modeling for 3D printing became more accessible to the public, with multiple open-source projects and cheaper hardware. Secondly, the 2000s saw the emergence of self-replicating 3D printers, like 2005s RepRap and 2008s Darwin. Finally, multiple DIY 3D printing devices entered the market. They were continuously updated by online communities, like Makerbot and Shapeways. This was truly the golden age in the history of 3D printing, but there’s more to come.

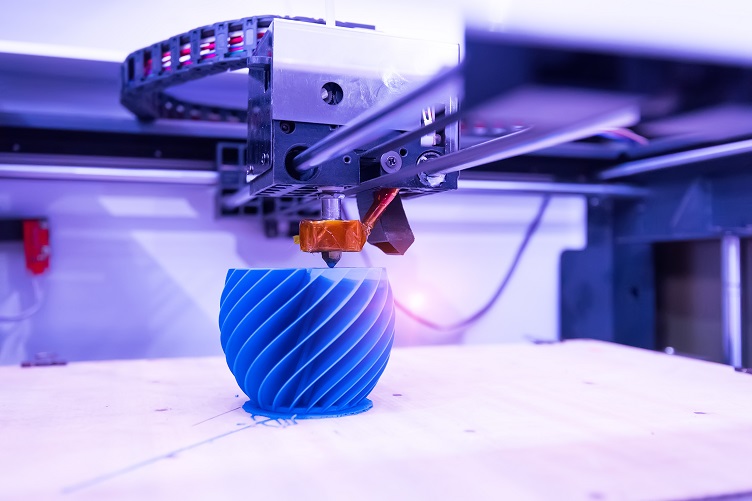

#5. The 2010s and the early 2020s: the future is now

At this point in history, 3D printing has reached previously unknown heights. If we showed its current capabilities to a person from 20 years ago, they would be convinced that we’re living in some kind of a sci-fi world. Currently, we have 3D printers that can print copies of themselves, 3D printed electronics, unmanned aircraft, cars, buildings, and the list goes on! Even a working-class person can afford a budget-friendly DIY 3D printer and learn how to operate it. 3D printed prosthetics have revolutionized medicine. Machining metal and plastic objects of all sizes is slowly being supplanted by additive manufacturing, due to the latter being cheaper and faster.

This opens wide new horizons for product manufacturers. 3D printing can help solve many of their problems with ease. Now, manufacturers can produce more goods faster than before and at lower costs. They also can forget about the struggle of creating new product designs due to rigid customization options available. And, of course, they got new effective techniques for prototyping.

The history of 3D printing is a story of continuous growth, and it shows. We already live in a world of what used to be science fiction thanks to this amazing technology. What does the future hold? Who knows? But one thing we can say for sure is that 3D printing can benefit any product brand, including yours!

Want to make your business more efficient with the help of 3D printed prototypes and goods? UFO3D studio can help with that! Order 3D modeling services to get 3D models for further printing!

Let us know if you’ve got an interesting project and want to work together!