3D Prototypes and Models: 5 Industries Reshaped by 3D Printing

3D printing, also known as additive manufacturing, may have once seemed like something from sci-fi Hollywood movies. But now it has become more of a reality than ever. Printed 3D prototypes and models are actively used in numerous spheres and significantly transform entire industries.

The concept of this technology was first laid out by a chemist and researcher David Jones back in 1974 in the New Scientist journal. In the following years, additive manufacturing has evolved greatly. Today, it is a powerful technology that allows to print anything from cups and keychains to houses and vehicles.

So, how does it work? The process starts with creating 3D models in CAD software. After that, a ready digital model is downloaded to a computer connected to a 3D printer. The latter is then used to create physical prototypes of the item by laying successive layers of materials such as ABS and PLA plastics, PVA, and others. The generation of objects through 3D printing can be done with different techniques such as selective laser sintering, stereolithography, multi-jet fusion, etc.

Using 3D prototypes has significant advantages for product brands. The benefits include boosted productivity, reducing manufacturing and storage costs, and the ability to customize goods with ease. 3D models for printing can be used to make any products — for example, camera lenses or acoustic guitars. However, the technology has much more to offer. Join us to find out how 3D printing is reshaping 5 large important industries!

Traditional methods of manufacturing jewels, like handcrafting and lost-wax casting, are time-consuming and expensive. Also, if there are mistakes in the design of the ready piece, remaking it using classic techniques requires much additional effort and expenses. But with the use of 3D prototypes and models, jewelry can be both within budget and easily customizable. That is because a 3D printer precisely reflects the shape and dimensions of even a very complicated CG object, which prevents errors in the final piece. Also, CAD models can be easily changed, which helps to customize jewels.

What’s more, additive manufacturing opens nearly unlimited opportunities for jewelry designers’ creativity. It allows for creating the most sophisticated and unusual pieces quickly, with impressive accuracy and precision. Also, it solves the problem of some jewels being too heavy and cumbersome. Lightweight materials like powder plastic make 3D printed jewelry easy to wear. There is also an option to produce large jewels filled with lattices or even hollowed ones instead of making them solid inside.

#2. Automotive industry

This industry has made a significant shift to 3D printing over the last years. In this sphere, the technology is mainly used for rapid prototyping but also the creation of tooling and sometimes even end parts of vehicles. There are plenty of automotive brands that use 3D prototypes and models. The list includes giants as Ford, Mercedes-Benz, Honda, Kia, Toyota, and BMW. Additive manufacturing helps these brands keep production cycles as short as possible and lower their costs. Also, it aids automotive companies in the fast and effective customizing of their vehicles.

Ford Motor Company was among the earliest adopters of this trend: they purchased one of the first 3D printers in the world around 30 years ago. This year, the company is launching the 2020 Ford Mustang Shelby GT500, which was developed with the help of additive manufacturing. The design evaluation and testing of the car were done using 3D prototypes and models. The final product will feature 3D printed parts as well — it will have two brake components created with 3D printers.

#3. Fashion

Today, 3D printing is making its first steps in fashion. It all started with the designer Danit Peleg who undoubtedly disrupted the industry in 2015. Using 3D modeling for 3D printing, she created her entire graduate collection of 3D printed apparel — the first of its kind in the world. Since then, many other designers have followed in her footsteps.

As for now, 3D printed clothing can rarely be seen outside the runways. 3D printers are used in fashion mostly to create accessories or features like buttons. But the future looks much more promising.

Once the industry adapts to the new technology, 3D prototypes and models will help fashion designers faces multiple challenges. One of them is that tailor-made clothes are now expensive and not available to everyone. But once the apparel will be 3D printed, custom-made garments will become a part of the mass-market. What’s more, the technology will give designers more creative freedom and room for innovation, since a 3D printer can easily and accurately produce even the most complex pieces of clothing.

Another problem that 3D printed apparel will solve is ecology-related. Now, the fashion industry produces much waste in the form of textile scraps and dyes for coloring fabrics that pollute water. Also, the massive production of clothes leads to air pollution. But with 3D prototypes and models, the industry will become more environmentally friendly. The process of creating garments with 3D printers will solve the problem of excessive wastage. Also, as it will be possible to make clothing on demand, the need for its storage will be eliminated too.

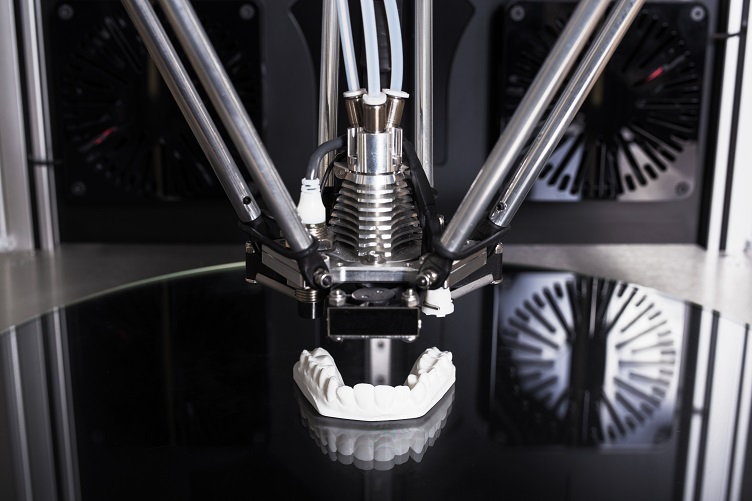

#4. Medicine

The applications of 3D prototypes in the field of medicine have become essential in the last years. 3D printing technologies have been used to generate arms, legs, and ears prosthesis, synthetic cartilage for knee and hip replacements. The innovation also helps dentists, allowing them to have 3D printed braces, crowns, and dentures made. What’s more, expecting parents can benefit from the technology by requesting a 3D printed fetus of their unborn child based on the ultrasound scan!

Another important application of 3D prototypes and models in medicine is in surgery. A medical professional can now print a 3D model of the patient’s organ they need to operate from a CT scan. It helps to understand their unique anatomy and train before the procedure.

And there is even more to come. In 2019, the scientists created a lung-mimicking air sac that functions similarly to a real organ. The development of such prototypes gives hope to many patients all over the world who are on transplant waitlists. When scientists learn to 3D print human organs, it will save thousands of lives.

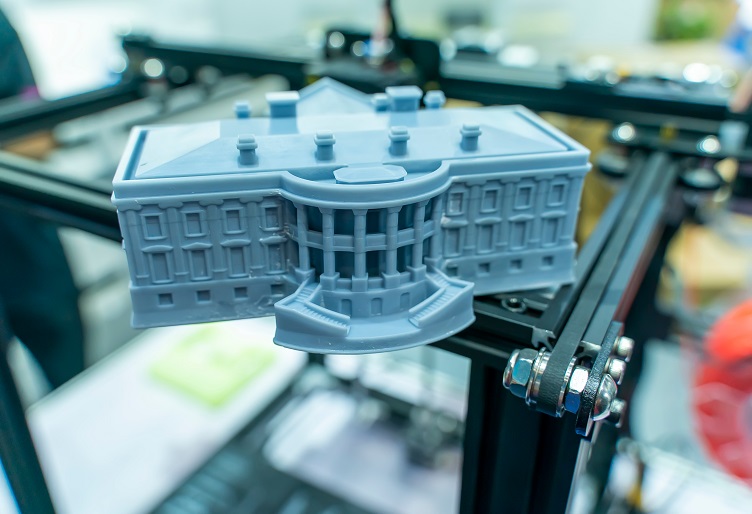

#5. Architecture

No discussion about 3D printing would be complete without talking about its influence on architecture. At the beginning of 2019, ArchDaily predicted it as a trend that would affect the industry. So, how exactly does the technology change the face of architecture? First of all, it allows architects to make precise physical models of their designs without meticulous handwork. Also, it allows to print things like lamps and sculptures and use them as end products in interior design.

What’s more, 3D prototypes and models have been used to create affordable housing. This year, 50 families will move into the first 3D-printed community in the world in rural Mexico. Their new homes were created using a giant 33-foot long 3D printer. Also, this May, six people who were previously homeless will move to their brand new 3D printed dwellings in Austin, Texas. So, the technology is promising to solve the rampant global issue of homelessness.

As for now, the most impressive use of 3D printing in architecture has come from the AI SpaceFactory. In 2019, this company has been commemorated by NASA for its project MARSHA that won the “Mars Habitat” challenge. It was a 15-feet-tall 3D printed prototype of a building that had been designed for the life of people on the Red Planet.

3D prototypes and models are helping professionals in multiple spheres, including jewelry and fashion design, and the automotive industry. They are also used in the medical field to protect health and save lives and in architecture to provide affordable housing. There is no doubt that in the future 3D prototypes will continue to transform different areas of our lives and make them better than ever before.

Need professional 3D modeling services to get CG models for further 3D printing? Contact UFO3D and we will help you with that!

Let us know if you’ve got an interesting project and want to work together!